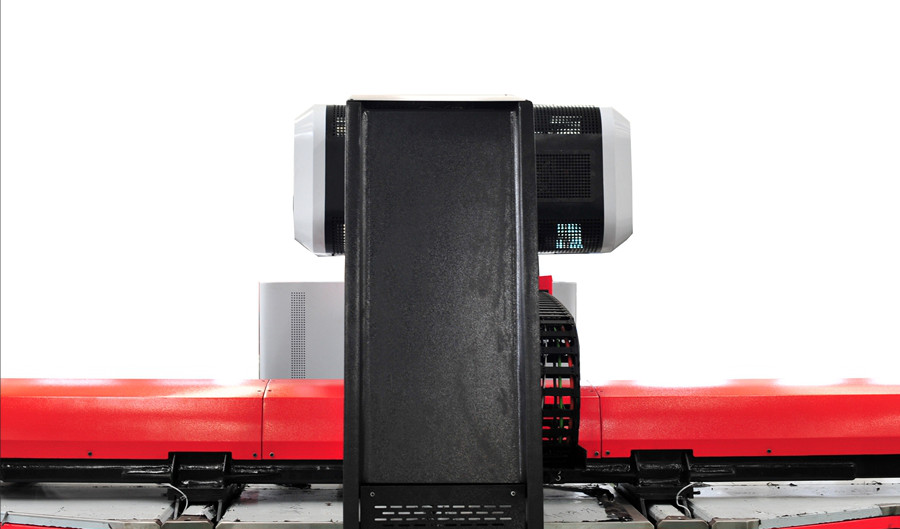

Makina apamwamba kwambiri a CNC Turret Punch

1. Single servo motor driven system, imagwiritsa ntchito torque yayikulu yoyendetsedwa ndi ma servo motor ndi makina oyendetsa omwe ali ndi mphamvu zambiri kuti azindikire kugwiritsa ntchito mphamvu zochepa, kutulutsa mphamvu kwambiri, magwiridwe antchito odalirika komanso kukonza bwino.

(1) Liwiro losinthika ndi sitiroko

a. The nkhonya sitiroko akhoza kusankhidwa malinga makulidwe a pepala basi, kuwongolera bwino ntchito.

b. Kuthamanga kwa nkhonya kumasinthika panthawi iliyonse ya siteshoni iliyonse,

c. makina amatha kuzindikira kuthamanga kwambiri panthawi yothamanga yopanda kanthu komanso kuthamanga pang'ono panthawi ya nkhonya yeniyeni, motere, khalidwe la nkhonya likhoza kukonzedwa bwino, ndipo palibe phokoso panthawi ya nkhonya.

(2). Dongosololi limakhala ndi chitetezo chopitilira apo komanso zida zodzitetezera pamakina.

(3). Mphamvu ya nkhonya imatha kusinthidwa zokha malinga ndi makulidwe a pepala ndi liwiro la nkhonya kuti nkhonya ifike pamlingo wapamwamba.

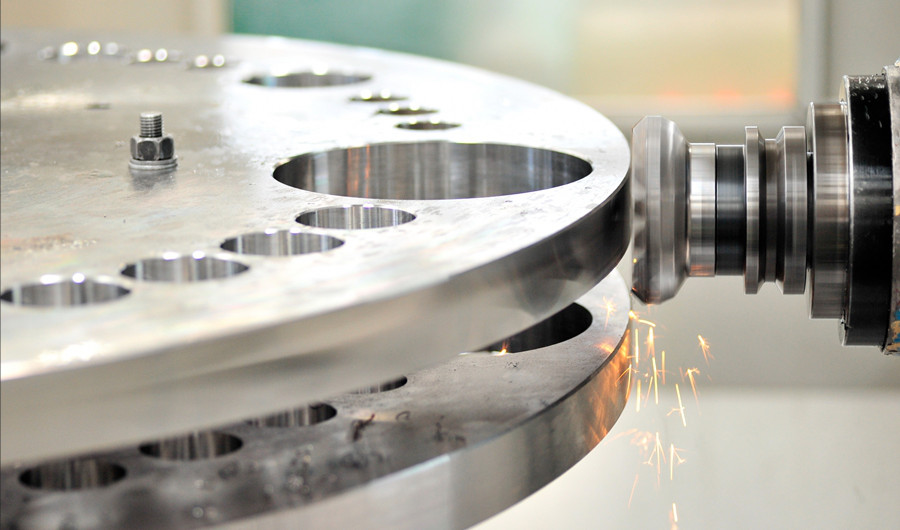

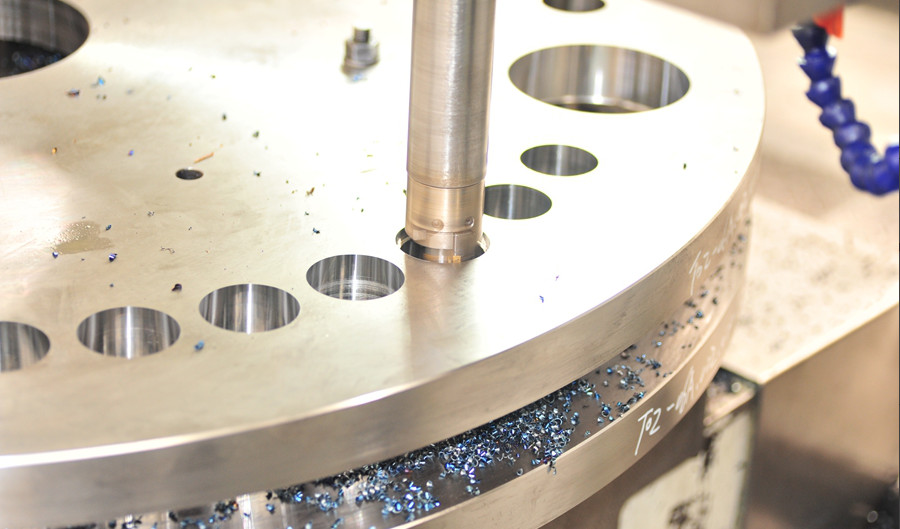

2. Turret yokhala ndi bushing ndi njira ziwiri

Turret imakonzedwa ndi chipangizo chapadera kuonetsetsa kuti coaxiality chapamwamba ndi m'munsi turret ndi kukulitsa moyo utumiki tooling; bushed turret imathandizira kapangidwe ka turret kukulitsa moyo wautumiki; zida zazitali zitha kugwiritsidwa ntchito kukulitsa kulondola kwa chitsogozo ndikukulitsa moyo wautumiki wa zida (pa pepala lakuda).

3. Zotengera za pneumatic, mafuta ndi magetsi zimatsimikizira kudalirika kwa makina onse.

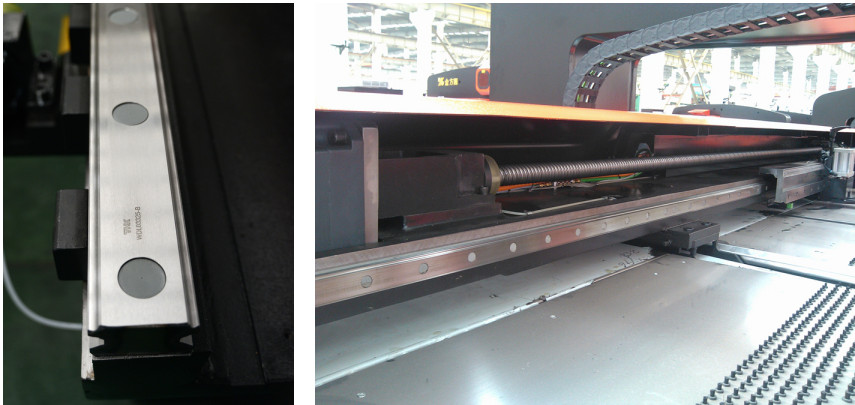

4. Njira yayikulu yotsogola ndi ma ballscrew ochokera ku Japan kapena Germany amatsimikizira kudyetsa kwakukulu kolondola.

5. Burashi yolimba ndi mpira wosanganiza worktable amachepetsa phokoso ndi kugwedera pamene akuthamanga komanso amateteza pepala pamwamba.

6. O-mtundu welded chimango wakhala vibrated kwa kawiri, nkhawa wakhala zichotsedwa kwathunthu. Chimangocho chimakonzedwa ndi Germany SHW dual-side pentahedron processing center nthawi imodzi, palibe chifukwa chopanganso kachiwiri.

7. Chingwe choyandama chokhala ndi mphamvu yayikulu yolumikizira chimatsimikizira kudyetsa kokhazikika; chonyamulira chophatikizika chimatsimikizira kukhazikika bwino komanso kuyenda kosavuta kwa clamp.

8. Dongosololi limawonetsedwa ndi ntchito yachitetezo chachitetezo chodziwikiratu kuti mupewe kuwonongeka kwa zida ndi kuwongolera, kuonetsetsa kuti pulogalamuyo ikuyenda mosalekeza.

9. Auto-index imatengera gudumu lolondola kwambiri la nyongolotsi ndi makina a nyongolotsi, kuwonetsetsa kulondola kwambiri. The Max. tooling awiri akhoza kufika 88.9mm ndi auto-index akhoza kukodzedwa kwa 4 nos.

10. Mapangidwe ophatikizika amtengo kuti apange chonyamulira ndi mtengo kukhala gawo limodzi, kukulitsa kulimba ndikubweretsa malo olondola. Makinawa amatha kuyenda mokhazikika panthawi yodyetsera mwachangu ndipo amathetsa kupatuka kwa nkhwangwa za X ndi Y.

11. X axis: imagwiritsa ntchito servo motor kuti iyendetse oyendetsa mipira yolondola kwambiri ndipo chonyamuliracho chimakhala chokhazikika komanso chopepuka. Y axis: servo motor imayendetsa mwachindunji choyikamo chomwe chimalumikizidwa ndi kanjira ka makina, mtengo wamtundu wogawanika umakhazikika ndi rack yodyera, ndipo mphamvu yochitira izi imaperekedwa kumakina amakina & pansi kudzera pakudyetsera rack ndi kanjira kuti muchepetse kugwedezeka kwa mtengowo. Kapangidwe kameneka kamawonetsedwa ndi mawonekedwe a kuuma bwino, kulemera kwake, kutsika kochepa, komanso kuyankha bwino kwamphamvu m'dongosolo lonse la chakudya, kuthamanga kokhazikika komanso kulondola bwino.

12. Dongosolo lapakati lopaka mafuta limatengedwa kuti litumize mafuta odzola kumalo opangira mafuta mwachindunji, kuchepetsa kukangana kwa awiriawiri ogwira ntchito ndikuwonjezera moyo wautumiki.

13. Kusinthana kwa pepala-kusintha ndi kusintha kwa pepala-anti-stripping kumatengedwa.

| Ayi. | Dzina | Qty. | Ndemanga |

| 1 | Mndandanda wazolongedza | 1 seti | |

| 2 | Sitifiketi Yabwino | 1 seti | |

| 3 | Mechanic Operation Manual | 1 seti | |

| 4 | Buku la Electrical Operation Manual | 1 seti | |

| 5 | Chojambula cha maziko | 1 seti | |

| 6 | Chojambula Chachikulu Chamagetsi | 1 seti | |

| 7 | Auto-program Software System Documents | 1 seti | |

| 8 | DBN Electrical Principal Drawing | 1 seti | |

| 9 | Buku la zida | 1 seti | |

| 10 | Buku la CNC system | 1 seti | |

| 11 | Kujambula kwa Zida | 1 seti |

| Ayi. | Dzina | Gauge | Qty. |

| 1 | Spanner ya mitu iwiri | 5.5 × 7-22 × 24 | 1 seti |

| 2 | Spanner yosuntha | 200 | 1 ayi. |

| 3 | Socket Head Spanner | S1.5-S10 | 1 seti |

| 4 | Cross Screwdriver | 100 × 6 pa | 1 ayi. |

| 5 | Mfuti ya Grease | Mtengo wa HS87-4Q | 1 ayi. |

| 6 | Mafuta Opaka Pampu Compressor Mfuti | SJD-50Z | 1 ayi. |

| 7 | Mfuti yothamanga kwambiri | 1 seti | |

| 8 | T mawonekedwe amtundu | M14 × 1.5 | 1 ayi. |

| 9 | Njira yosinthira | M12 PNP SN=2 lotseguka | 1 seti |

| 10 | Njira yosinthira | M12 PNP SN=2 pafupi | 1 ayi. |

| 11 | Spanner | T09-02,500,000-38 | 1 ayi. |

| 12 | Spanner yosinthira silinda ya gasi | 1 seti | |

| 13 | Chitoliro chofewa | Ø 12 | 1 ayi. |

| 14 | Pini yofewa | Chithunzi cha KQ2H12-03AS | 1 seti |

| 15 | Zigawo za maziko | 1 ayi. |

| Ayi. | Dzina | Gauge | Qty. | Ndemanga |

| 1 | Gulu la zida za clamp | 3 ndi. | T02-20A.000.000-10C T02-20A.000.000-24A | |

| Khomba la portective board | 6 ndi. | T02-20A.000.000-09C Kapena T02-20A.000.000-23A | ||

| 2 | Spring Small screw mu clamp | M4x10 | 20 no. | T02-06,001,000-02 |

| M5x12 | ||||

| 3 | screw in clamp Inner screw | M8x1x20 | 20 no. | |

| 4 | Kumeta ubweya | 30T | 2 no. | T09-16.310,000-0.1.2 |

| 5 | Mkati | M8x1x20 | 4 ndi. |

FANUC CNC system ndi makina apadera a CNC opangidwa ndi Japan FANUC makamaka pofuna kukwaniritsa mawonekedwe a makina amtunduwu, kukonza makina odalirika kwambiri.

Ine, Makhalidwe a System

1. Zojambula ndi nkhonya ntchito;

2. Pulogalamu yabwino ya G code kuti igwire ntchito mosavuta;

3. Universal RS232 muyezo doko kulankhulana ndi kompyuta mosavuta;

4. MwaukadauloZida zonse digito servo galimoto ndi servo dongosolo;

5.10.4 ″ chiwonetsero chazithunzi cha LCD;

6. Ndemanga za Pulse encoder semi-loop;

7. EMS kukumbukira: 256K;

8. Pulogalamu yam'munda, pulogalamu yaofesi;

9. Chiwonetsero cha Chitchaina ndi Chingerezi;

10. Ntchito ya kayeseleledwe kazithunzi;

11.One lalikulu mphamvu PCMCIA khadi zosunga zobwezeretsera dongosolo chizindikiro, makwerero kujambula ndi processing pulogalamu, ndi kuzindikira njira Intaneti wa lalikulu mphamvu processing pulogalamu;

12. Kuwonjezeka kwa gawo laling'ono kwambiri, kuzindikira malo ad servo control kuti azindikire kuthamanga kwambiri ndi ntchito yolondola kwambiri;

13. Batani la ntchito pa gulu likhoza kufotokozedwa molingana ndi zofunikira zenizeni;

14. Super high speed clutch data zingwe ndi kugwirizana pang'ono chingwe;

15. Kuphatikiza kwakukulu, mapulogalamu apadera. Nthawi yochepa yoyambira, deta sidzatayika ngati mphamvu ikusowa mwadzidzidzi;

16. Kusungirako zidutswa za 400 za pulogalamu.

1. Nkhwangwa zozungulira: X, Y nkhwangwa zozungulira: T, C nkhwangwa, nkhonya: Z axis;

2. Alamu yamavuto amagetsi monga sitiroko yopitilira muyeso.

3. Ntchito yodzifufuza.

4. Ntchito ya malire ofewa.

5. Khodi ya Universal G ya pulogalamu;

6. Ntchito ya chipukuta misozi;

7. Ntchito ya screw mtunda chipukuta misozi;

8. Ntchito ya reverse gap chipukuta misozi;

9. Ntchito ya ma coordinates kupatuka;

10. Ntchito ya reposition;

11. Ntchito ya AUTO, MANUAL, JOG mode;

12. Ntchito yachitetezo cha clamp;

13. Ntchito ya loko ya kaundula wamkati;

14. Ntchito ya pulogalamu ya parameter;

15. Ntchito ya pulogalamu yaing'ono;

16. Ntchito yoyikira mwachangu ndi nkhonya loko;

18. Ntchito ya M code;

19. Mtheradi ndi increment pulogalamu;

20. Kukhazikika, kulumpha mopanda malire.

Kuyambitsa pulogalamu yamapulogalamu

Timatengera CNCKAD kuchokera ku METALIX Company. Pulogalamuyi ndi pulogalamu yathunthu ya mapulogalamu a CAD/CAM kuyambira pakupanga mpaka kupanga. Ndi kasamalidwe ka laibulale ya nkhungu, makina osankhidwa amtundu wodziwikiratu, kukhathamiritsa kwa njira ndi ntchito zina, zitha kupangidwa zokha ndi njira za CAD zojambula NC. Mutha kukwaniritsa pulogalamu ya gawo limodzi, kupanga nesting ndi phukusi lathunthu.

Ntchito ya DrawingCNCKAD zithunzi zamphamvu, zosavuta ndi mwachilengedwe ntchito, kuwonjezera pa muyezo kujambula ntchito malinga ndi makhalidwe a pepala zitsulo, anawonjezera njira zina zapadera zojambula monga incision, kuzungulira, makona atatu, ngodya yoyenera ndi mawonekedwe contour, kusinja, fufuzani kusintha ndi kuwongolera basi, kudula kapena kupondaponda, zilembo Chinese DXF/IGES/CADL/DWG file athandizira etc.

b) Ntchito Yankhonya

Zowonetsedwa ndi nkhonya zodziwikiratu, nkhungu yapadera, zolozera zokha, kusamutsa basi, kudula m'mphepete, ndi ntchito zina.

c) Ntchito Yometa

Zodziwikiratu za contour fufuzani ndikuwongolera magawo amtundu wazinthu, makulidwe, odulidwa amodzi, odulidwa, kusuntha kukameta ubweya, ndi ntchito zina, kukonza mbale zodziwikiratu.

d) Post Processing

Makina opangira okha kapena ophatikizana amakhudza njira zonse: kupondaponda, laser, plasma, moto, kudula madzi ndi mphero.

Kukonzekera kwapamwamba kwa positi kumatha kutulutsa mitundu yonse yamakhodi a NC, njira yothandizira, pulogalamu yayikulu, monga kukhathamiritsa kwa njira yazida ndi kasinthasintha kakang'ono ka nkhungu, jekeseni wothandizira, ntchito zamakina akuyamwa vacuum monga zakuthupi ndi kutsetsereka kwa block.

Kusamutsa pulogalamu kumakina ena kumangofunika kudina pang'ono ndi mbewa.Izi zimachokera ku njira ya CNCCKAD positi, pochotsa mafayilo ochulukirapo apakompyuta omwe amapangitsa kuti ntchitoyo ikhale yabwino kwambiri.

e) CNC Graphical kayeseleledwe

Mapulogalamu amathandizira kayeseleledwe kalikonse ka CNC, kuphatikiza kachidindo ka CNC kolemba pamanja, kuwongolera ndikosavuta kwambiri, pulogalamuyo imatha kuyang'ana zolakwika, monga kutayika kwa magawo otayika ndi zolakwika zamtunda, ndi zina zambiri.

f) Kusintha kuchoka ku NC kupita ku Drawing

Kaya yolembedwa ndi dzanja kapena nambala ina ya NC, imatha kusinthidwa kukhala zithunzi.

g) Lipoti la Tsiku

Mutha kusindikiza lipoti la data, kuphatikiza zidziwitso zonse monga kuchuluka kwa magawo, kukonza zambiri monga nthawi, mawonekedwe a nkhungu etc.

h) Kutumiza kwa DNC

Kutengera mawonekedwe a Windows a gawo lopatsirana, kuti kufalitsa pakati pa PC ndi zida zamakina ndikosavuta.

1), Thandizani panopa zitsanzo zonse za CNC turret nkhonya, laser kudula makina, plasma kudula makina ndi lawi kudula makina ndi zida makina.

2)), Thandizani ndondomeko yonse ya ntchito CNC zida, kuphatikizapo kujambula, basi kapena kukambirana processing, positi processing, CNC kayeseleledwe pulogalamu, Buku ndi basi kudula, NC wapamwamba download ndi kweza etc.

3)), Mutha kulowetsa mwachindunji Autocad, SolidEdge, SolidWork ndi CadKey etc kuphatikiza mafayilo onse otchuka a CAD omwe amapangidwa.

4) 、 Mapulogalamu amathandizira zida zosiyanasiyana zowongolera manambala, amatha kuyika mbali za NC kupanga mafayilo amitundu yosiyanasiyana, pazida zingapo nthawi imodzi panthawi yokonza.

Kuyikanso Kokhazikika

Pamene mbale kukula ndi lalikulu kuposa osiyanasiyana osiyanasiyana, makina basi kukonzanso malo, ndiyeno basi kwaiye malangizo udindo; ngati wosuta ali ndi zofunika zapadera, akhoza kusinthidwa kapena zichotsedwa paokha re malo malangizo.

Kupewa kwachingwe chokhazikika

Malangizo omwe amapangidwa podziyika okha omwe angapangitse kuti chotchinga chipewe kufa, kuchepetsa zinyalala; kaya mbale ndi gawo kapena mbali zingapo za mbale yachitsulo, imatha kuzindikira ntchito yopewera zoletsa.

Mzere wa zinthu processing

Pofuna kuchepetsa mapindikidwe a zinthu mu ndondomeko kupondaponda, Mzere zinthu processing njira akhoza anatengera, ndi kudula chida angagwiritsidwe ntchito kutsogolo kapena kumbuyo kwa malangizo nthambi.

Njira yodulira

Kuphatikizidwa ndi ntchito ya nkhonya wamba m'mphepete, kukhomerera kodziwikiratu komwe kumatha kumenya zinthu zosweka kuzungulira m'mphepete.

Kudekha kumodzi kumangoyenda zokha

Ndi makina osunthika ang'onoang'ono amatha kupangidwa ndi pulogalamuyo yongosuntha basi kudzera mu malangizo a NC.

Kuzungulira kocheperako

Njira yocheperako yosinthira kufa imatha kuchepetsa kuvala kwa ma indexing station ndikuwongolera magwiridwe antchito.

Ntchito ya Mitundu Yambiri Yokhomerera

Ntchito yokhomerera pamakona atatu, kukhomerera kwa bevel, kukhomerera kwa arc ndi njira ina yapadera komanso yogwira mtima.

Ntchito ya Strong Auto Punching

Mawonekedwe a Automatic Punching akuphatikiza kulumikizidwa kwapang'onopang'ono, kusankha mwanzeru nkhungu komanso kuchuluka kwa ma alarm ndi ntchito zina.

I) Ntchito yodula yokha

METALIX CNCKAD ili ndi gawo la AutoNest lomwe ndi pulogalamu yeniyeni yopangira zisa, yomwe imatha kuzindikira kukhathamiritsa kwazitsulo zonse zaukadaulo.

1. Mpweya: kuthamanga kwa ntchito kuyenera kukhala kopitilira 0.6mPa, kuyenda kwa mpweya: kuposa 0.3m3/min.

2. Mphamvu: 380V, 50HZ, kusinthasintha kwamagetsi: ± 5%, mphamvu yamagetsi ya 30T ndi 45KVA, chingwe champhamvu ndi 25mm², chophwanya ndi 100A. Ngati magetsi sali okhazikika, stabilizer imafunika, ngati pali kutuluka kwa magetsi, chitetezo chikufunika.

3.Hydraulic mafuta: (SHELL) Tonna T220, Kapena mafuta ena owongolera ndi kudzoza njanji.

Kupaka mafuta: 00 # -0 # Kuthamanga kwambiri mafuta (GB7323-94) lingaliro: pansi pa 20 ° C ntchito 00 # Kuthamanga kwambiri mafuta, pamwamba pa 21 ° C ntchito 0 # Kuthamanga kwambiri mafuta

| Mtundu | Dzina | Ndemanga | Kutentha |

| Chipolopolo | EPO | 0 # Mafuta opanikizika kwambiri | 21 ° C pamwamba |

| Chipolopolo | GL00 | 00 # Mafuta opanikizika kwambiri | 20 ° C pansipa |

3. Kutentha kwa chilengedwe: 0°C - +40°C

4. Chinyezi cha chilengedwe: chinyezi chachibale 20-80%RH(un-condensation)

5. Khalani kutali ndi kugwedezeka kwamphamvu kapena kusokoneza maginito amagetsi

6. Malo okhala ndi fumbi pang'ono, opanda mpweya wakupha

7. Konzani maziko molingana ndi zojambula za maziko

8. Wogwiritsa ntchitoyo asankhe katswiri kapena mainjiniya kuti amuphunzitse, yemwe ali ndi maphunziro omwe ayenera kukhala atamaliza maphunziro ake kusukulu yaukadaulo yaukadaulo, ndikukonzekereratu kwa nthawi yayitali.

11.Ayenera kukonzekera maziko molingana ndi zojambulazo

12. Chotsegula cha 65mm spanner wrench, ndodo yothandizira afterburner, kusintha mlingo wa maziko.

13. Mafuta opitilira 5 malita amafuta oyera, nsanza zingapo, mfuti, mafuta opaka mafuta, pafupifupi malita 1 opangira zida zamakina ndi nkhungu.

14 ndi Ф10 * 300 imodzi ndi Ф16 * 300 ndodo zamkuwa zopangira nkhungu. Mtengo wautali (fuselage ndi mtengo zimayikidwa padera, komanso kukonzekera mayunitsi otumizidwa)

15 choyimira choyimba (0-10mm) chomwe chimagwiritsidwa ntchito kuthetsa vuto la X ndi Y axis perpendicularity.

16 zida zikafika kufakitale, konzani magalimoto a 20T kapena crane pazida zonyamulira

17.Ngati V olamulira ali okonzeka ndi madzi chiller motor, zogwirizana kuzirala wapakatikati ayenera kukonzekera, voliyumu ndi 38L.

Zinthu zina zomwe sizinafotokozedwe zimafunikira kutanthauzira kwina ndi kugwirizana

CNC Turret nkhonya Machine makina;numerical control turret punch press;servo drive turret punch press;turret punch press for sale

| Ayi. | Kufotokozera | Chigawo | Machine Model | ||

| Mtengo wa MT300E | |||||

| 1 | Max. Punch Force | kN | 300 | ||

| 2 | Main Driving Type | / | Amayendetsedwa ndi injini imodzi | ||

| 3 | CNC System | / | FANUC CNC dongosolo | ||

| 4 | Max. Kukula Kwa Mapepala | mm | 1250*5000 (ndi malo amodzi) | 1500 * 5000 (ndi malo amodzi) | |

| 5 | No. ya Clamp | ayi. | 3 | ||

| 6 | Max. Kukonza Makulidwe a Mapepala | mm | 3.2/6.35 | ||

| 7 | Max. Punch Diameter pa Nthawi | mm | Φ88.9 | ||

| 8 | Main Striker Stroke | mm | 32 | ||

| 9 | Max. Punch Hit pa 1mm Pace | hpm pa | 780 | ||

| 10 | Max. Punch Hot pa 25mm Pace | hpm pa | 400 | ||

| 11 | Max. Nibbling Speed | hpm pa | 1800 | ||

| 12 | Nambala ya Repositioning Cylinder | set | 2 | ||

| 13 | No. ya Station | ayi. | 32 | ||

| 14 | Nambala ya AI | ayi. | 2 | ||

| 15 | Nambala ya Controlling Axis | ayi. | 5 (X, Y, V, T, C) | ||

| 16 | Mtundu wa Zida | / | Mtundu Wautali | ||

| 17 | Mtundu wa Worktable | / | Pansi 3.2mm: Full burashi yokhazikika worktable (Mipira yokweza kuti muyike ikhoza kuwonjezeredwa ngati njira) | ||

| Pamwamba 3.2mm: Mipira yonse yogwira ntchito | |||||

| 18 | Max. Kudyetsa Liwiro | X axis | m/mphindi | 80 | |

| Y axis | 60 | ||||

| XY Zogwirizana | 100 | ||||

| 19 | Liwiro la Turret | rpm pa | 30 | ||

| 20 | Kuthamanga kwa Zida Zozungulira | rpm pa | 60 | ||

| 21 | Kulondola | mm | ±0.1 | ||

| 22 | Max. Katundu Kukhoza | Kg | 100/150 pa mpira worktable | ||

| 23 | Main Motor Power | kVA | 45 | ||

| 24 | Tooling mode | / | palokha kudya disassembly mtundu | ||

| 25 | Kuthamanga kwa Air | MPa | 0.55 | ||

| 26 | Kugwiritsa Ntchito Mpweya | L/mphindi | 250 | ||

| 27 | CNC Memory Capacity | / | 512k pa | ||

| 28 | Clamp dead zone kuzindikira | / | Y | ||

| 29 | Mapepala-anti-stripping Switch | / | Y | ||

| 30 | Kusintha kwa Anti-Sheet-Deformation | / | Y | ||

| 31 | Kukula kwa Outline | mm | 5350×5200×2360 | 5850×5200×2360 | |

| Ayi. | Dzina | Mtundu | Gauge | ||

| 1 | CNC System | Mtengo wa FANUC | OI-PF | ||

| 2 | Woyendetsa Servo | Mtengo wa FANUC | AISV | ||

| 3 | Servo Motor (X/Y/C/T axis) | Mtengo wa FANUC | AIS(X,Y,T,C) Makina apadera a V axis | ||

| 4 | Njira | THK | HSR35A6SSC0+4200L (X:2500) | ||

| HSR35A3SSC1+2060L-Ⅱ (Y:1250) | |||||

| HSR35A3SSC1+2310L-Ⅱ (Y:1500) | |||||

| 5 | Mpira | THK | BLK4040-3.6G0+3016LC7 (X:2500) | ||

| BLK3232-7.2ZZ+1735LC7T (Y:1250) | |||||

| BLK3232-7.2ZZ+1985LC7T (Y:1500) | |||||

| 6 | Kubereka Molondola | NSK/Koyo | 25TAC62BDFC10PN7B/SAC2562BDFMGP4Z | ||

| Zithunzi za 30TAC62BDFC10PN7B/SAC3062BDFMGP4Z | |||||

| 7 | Zigawo za pneumatic | Magawo atatu | Zithunzi za SMC | Chithunzi cha AC30A-03D | |

| Valve ya Solenoid | Chithunzi cha SY5120-5D-01 | ||||

| Muffler | AN10-01 | ||||

| Silinda | Mtengo wa CP96SDB40-80-A93L | ||||

| 8 | Electrical System | Wophwanya | Schneider | / | |

| Contact | Schneider | / | |||